Monotube Vs Twin-Tube – What is the Difference? What is Better?

There are many rumors and discussions regarding which type of shock absorber is better, the Mono-tube or the Twin-tube? Mono-tube and twin-tube are known as two different types of suspension systems that each work in very different ways.

Mono-Tube

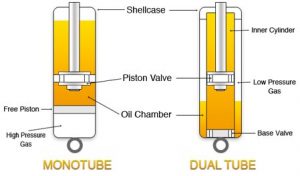

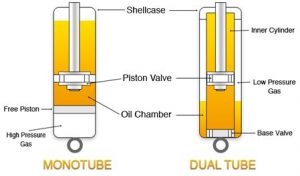

In a mono-tube shock absorber, the shocks components are contained within one tube. A mono-tube system contains a shell case which works as a cylinder. Within that cylinder you would find a piston valve, oil, and gas. The construction of a mono-tube does also include some differences compared to the twin-tube design. A mono-tube design utilizes a free piston which separates the oil chamber from the gas chamber within the shell case.

Twin-Tube

In a twin-tube shock absorber there are 2 cylinders: 1 cylinder is set inside the shell case, and the second cylinder contains the piston valve which moves up and down within this second cylinder known as the “inner cylinder”. With a twin-tube design, there is no piston or barrier between the oil chamber and gas chamber.

Pros and Cons of Mono-Tube Shock Absorbers

Pros of Mono-Tube

- As temperature increases, oil is able to release heat with less effort.

- Zero restrictions on installation angles.

- Less prone to cavitation

- Larger oil capacity and greater heat dissipation allows for a stable damping force that is continuous.

- Air is not able to penetrate the oil or gas since they are completely separated.

- 100% efficiency through all temps.

- The piston valve is bigger and wider in a mono-tube design which allows for a wider area of pressure. In turn this means the shock can create even a subtle damping force precisely.

Cons of Mono-Tube

- A stiffer ride is expected because an injection of high pressured gas is required in the structural design.

- This high pressured gas can also lead to a higher amount of stress on seals which can cause more friction.

- More expensive to manufacture

- When there is external damage or force on the shell case, that directly affects the inner cylinder.

- Since the oil and gas chambers are positioned next to each other, it is increasingly difficult to maintain sufficient stroke.

- The inverted design has more friction caused from more moving parts.

Pros and Cons of Twin-Tube Shock Absorbers

Pros of Twin-Tube

- Unlike the inverted design, friction can be stopped.

- External damage to the shell case does not effect the shock absorber.

- The twin-tube design provides a superior manufacturing process which keeps the cost of production low.

- Gas pressure is kept low thanks to the base valve, this creates a more comfortable ride.

- Low gas pressure reduces stress on seals and also keeps friction to a minimum.

- Sufficient stroke is attained with far less effort. This is because each oil and gas chamber are separated.

Cons of Twin-Tube

- The construction causes difficulties when installing.

- Aeration is possible since the oil and gas chambers are not separated.

- Size of Piston is greatly decreased compared to the mono-tube design.

- Oil capacity is reduced in comparison to the the mono-tube.

- Low Pressure – Generally very Soft

- Small Pistons, more prone to heat and limited on damping

- CAVITATION- Fluid and gas mix, exponential performance loss up to 35%

- 1 Directional Mounting

All ISC Suspension systems use the mono-tube design for performance purposes along with the fact that the pros of the mono-tube design greatly outweigh it’s cons.

Related Links

Why is it Important to Properly Align Your Suspension?

Monotube Vs Twin-Tube – What is the Difference? What is Better?

What is an Air Cup and How Do they Work?

BMW X-Drive Coilovers & Suspension

ISC Suspension Valving Options: Which One is Right for You?

SWIFT Springs; Optional Upgrade for many ISC Coilovers

Product Feature: ISC 240SX Rear TOE ARM

How to Setup a Drift Car – Proper Drift Settings

Triple S Coilover Springs – Does it Make a Difference?

What is the Best Coilover Ride Height for My Car?

ISC V3.1 Rear Adjustable Control Arms

Upgrades to Consider when Installing Coilovers

Should I install coilovers on my car?

What is the purpose of adjustable end links and how do they relate to my coilovers?

Difference between ISC N1 and Basic, which to choose?